"Pink House": Vertical Pharming of Bioreactor for Therapeutics Production

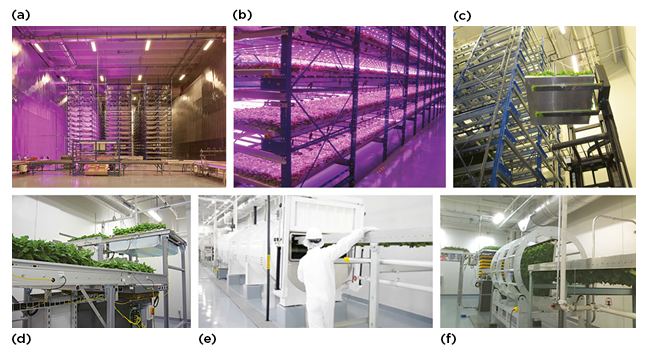

Last month the subject of speed and flexibility for protein expression using Plant Made Pharmaceuticals (PMPs) was discussed. This month, we’ll go deeper - and show you the attention to detail given to growing iBio CMO’s bioreactors – the small, fast-growing Nicotiana benthamiana plant. This iBio CMO facility, located in Bryan Texas, and dedicated solely to plant made pharmaceuticals, was built with hundreds of unique features. One of the many unique engineering projects contributing to the success of the facility was the development of a new generation of LED lights for hydroponic plant growth.  Figure 1 above: Hydroponic plant growth in the “Pink House” @ iBio CMO LLC. Formerly owned by Caliber Biotherapeutics, the facility was originally built as a cost-sharing project with DARPA as part of Project “Blue Angel”, a vaccine production acceleration project recommended by the US President’s Council of Advisors on Science and Technology. The facility was built to demonstrate that sub-unit vaccines could be produced rapidly in significant quantities. Fifty million doses of antigen were produced in twelve weeks from receipt of gene sequence. As this facility was being designed, every accepted method of design-build was re-examined.

Figure 1 above: Hydroponic plant growth in the “Pink House” @ iBio CMO LLC. Formerly owned by Caliber Biotherapeutics, the facility was originally built as a cost-sharing project with DARPA as part of Project “Blue Angel”, a vaccine production acceleration project recommended by the US President’s Council of Advisors on Science and Technology. The facility was built to demonstrate that sub-unit vaccines could be produced rapidly in significant quantities. Fifty million doses of antigen were produced in twelve weeks from receipt of gene sequence. As this facility was being designed, every accepted method of design-build was re-examined.

Nothing was taken for granted, and each step was optimized for speed of manufacture potential. The growing facility was designed to be “hardened” to hurricanes, tornadoes, etc. Therefore, the growth rooms were not greenhouses. Plants had to be grown on 100% artificial substrate. When you enter the grow room at iBio CMO, the sheer size of the room and the pulse of the huge HVAC system engages the senses. Each growing room is 100 x 150 feet and 5 stories high, with 14 layers of automated plant growth racks. A visitor immediately notices the violet/purple glow which envelops the room. This glow is the proprietary LED illumination system used to maximize growth of the plants.

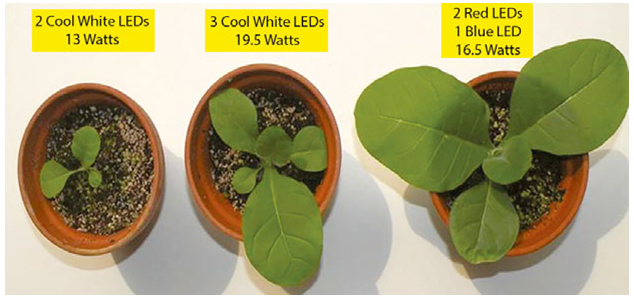

LED lighting was selected for the multitude of advantages the technology provides for plant germination and growth. Standard fluorescent lighting does not provide sufficient photic energy and its broad spectrum leads to inefficiencies for plant growth and energy usage. Both fluorescent and metal halide light are energy intensive and present localized heat load issues and require high voltage wiring. Higher environmental temperature uniformity is achieved with LED lighting at a much lower energy input. Computational flow dynamic modeling showed that < 1.5 degrees C of temperature variation across the entire plant production area was required to meet standards for plant growth uniformity. The lights are also low voltage and waterproof.

“A Photon is a terrible thing to waste”

Red and blue diodes were selected that match the action spectrum of photosynthesis (25% blue and 75% red). Other wavelengths are not productive. The LED’s are focused on the plants. Plants grown to usable maturity 20% faster in this system as compared to other commercial solutions. When growing 2.2 million plants, as an in process inventory, the impact on throughput is enormous. The lighting system also uses only 66% of the electricity of other commercial systems and delivers 166% more usable photic energy to the plants. More output of plants means more biomass growth for any given vaccine or therapeutic production campaign.

The small ornamental plant has a high leaf to stem ratio and is very prolific in hydroponic culture. N. benth. tolerates the transfection vectors and delivers maximum synthesis of heterologous proteins in 4-7 days after transfection. Scale-up of this bioreactor is a matter of growing more plants not re-engineering processes. Plants have all the eukaryotic cell machinery to accurately produce human and animal proteins. Thus, the bioreactor is the individual plant. Plants are well suited to express complex proteins such as monoclonal antibodies, and minimize risk by not supporting growth of human or animal pathogens. The iBio pilot facility can provide milligram to gram quantities of protein to development teams in weeks, not months and years. When the challenge is making enough product, quickly enough, PMPs and the “pink house” are a solution to consider.