Fast, Flexible, Scalable

Some estimates suggest that Continuous Manufacturing could shave 30%–50% off the cost of making drugs, and that production could be up to 90% faster than batch mode. Continuous Manufacturing can also reduce—and possibly eliminate—scale-up time. Unlike traditional manufacturing, it can be scaled for immediate demand and allow variable batch sizes, including smaller batches of specialty products. The company’s development goal is to operate 24/7 with throughput times as short as half a day.

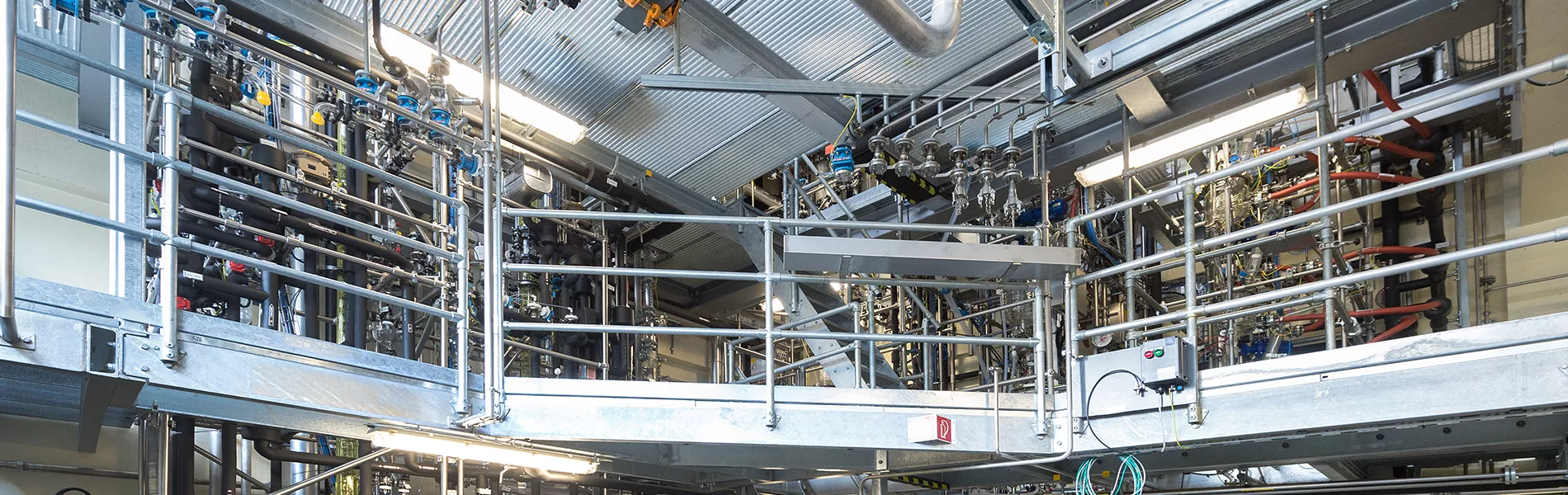

“The way we’ve built our facility is highly modular, like Lego blocks for chemists,” Krumme said. “You can build a lot of different things, not by changing the structure of any one block, but just by assembling blocks in different ways.”

Could this type of process alleviate the instances of drug shortages that are due, for example, to facility damage and other effects of natural disasters, such as last year’s hurricane in Puerto Rico?

“I would say not yet, but it can be an attractive tool if used properly. I can conceive if we standardized the Lego blocks into chemical production, we could be flexible in what is produced, where it’s produced, and how fast a new assembly could be built out of preexisting blocks. If used in the right way, we could create an agile industrial environment that would allow mitigation of drug shortages. It would be smart to go in this direction.”

Some estimates suggest that continuous manufacturing could have 30% - 50% off the cost of making drugs, and that production could be up to 90% faster than batch mode.

The idea of facilities being built out of components is reminiscent of the GE Healthcare Life Sciences FlexFactory (see article "The Rise of Biopharmaceutical Manufacturing in Asia"), the first of which was built for JHL Biotech in Wuhan, China. Prefabricated as 62 modules in Germany and shipped to China, the facility included intact cleanrooms. It will produce biosimilars for the domestic market.

“While continuous processing allows smaller batches of specialty products—and could be a helpful tool for producing personalized medicines—it is not playing in the same field as a drug like Novartis’s Kymriah, a biologic that is an extreme version of a specialized medicine,” Krumme said. “But it does let us manipulate the run time, whether that’s one hour, one day, or one week, and leads to a scalable batch size. It is, in this sense, a helpful tool for personalized medicine.”