Integrated Vapor-Phase Hydrogen Peroxide (VPHP) Decontamination Systems

Integrated VPHP systems offer a versatile, automated, sporicidal process for cleanroom suites, isolators, RABS, chambers, and pass-throughs.

The first portable vapor-phase hydrogen peroxide (VPHP) generators developed in the early 1990s were designed to dry, decontaminate, and aerate target enclosures efficiently while controlling pressure. Today, these generators, which typically use a closed-loop airflow pattern, are used predominantly on isolators, small rooms, and material air locks. 1 As users sought to enhance process automation, increase cleanroom suite sizes, shorten cycle times, and standardize data capture, integrated VPHP generators were developed. These could be tied in with the heating, ventilation, and air-conditioning (HVAC) system and controlled and monitored by the building management system (BMS).

Integrated generators are designed to flash-vaporize hydrogen peroxide precisely and consistently, and deliver predefined quantities of VPHP to the target enclosure. Unlike portable VPHP generators, integrated units work with an array of external air-handling components that deliver, distribute, and purge VPHP from the target enclosure. Collectively, this is called an integrated VPHP system. In some facilities, use of an integrated VPHP system is as common as other utilities, such as compressed air.

Integrated VPHP installations provide the well-known benefits of hydrogen peroxide vapor decontamination while enhancing process repeatability and decreasing labor and total costs. Other key benefits include:

- Sporicidal surface decontamination

- No residues

- Excellent material compatibility

- Lower toxicity than other gaseous treatments

- Highly automated, high-output, consistent, and continuous operation

- Very low operating cost: no manual labor, setup, or fans

- System is installed and maintained outside the clean area

- No cross-contamination via equipment or personnel moving between target enclosures

- Single unit can be configured via a manifold to decontaminate multiple enclosures.

BACKGROUND

Initial VPHP applications were focused predominantly on pharmaceutical sterility test and aseptic production applications by pairing isolators with portable VPHP generators. Although this configuration is still common for smaller sterility test and research isolators, many large production isolators now utilize integrated generators that work in concert with their air-handling systems to distribute and purge hydrogen peroxide, resulting in short, effective decontamination cycles. Once an isolator is cleaned and dried, hydrogen peroxide vapor is applied for biodecontamination and to achieve sterility on all exposed hard surfaces.

Since the early 1990s, vaporized hydrogen peroxide use has expanded from barrier isolators to cleanroom suites. With the goal of achieving 4- to 6-log bioburden reductions, users have either purchased portable VPHP generators or contracted with specialized service providers that deploy multiple networked portable units, power cords, and fans to treat areas that can exceed 3,000 cubic meters (m3). Gaseous biodecontamination can be obtained more cost-effectively when VPHP is deployed via an integrated system that is seamlessly incorporated into the HVAC system of classified production areas.

For successful integrated VPHP installation and optimal process performance, specialized user requirements may require a high level of cross-functional collaboration, with input from process engineers, automation programmers, quality, validation, and environmental health and safety personnel. Hundreds of integrated VPHP systems have been installed, primarily in Europe and Asia,2 providing clear evidence that this improved automated technology has gained industry acceptance.

PLANNING CRITERIA

The decision to implement a VPHP process begins with selecting either a portable or integrated system. The choice often depends on existing or planned infrastructure, technical resources, intended frequency/ease of use, and a favorable cost-of-ownership projection. A comparison is

shown in Table A.

Safety

Safety should always be a primary focus, even in the preliminary design phase. VPHP systems typically use concentrated liquid hydrogen peroxide in a range of 35%–59%; storage and handling of these containers should comply with health and safety rules. Preventing and detecting VPHP leaks from delivery piping or an enclosure should also be a primary concern. Hydrogen peroxide breaks down into oxygen and water, so exhausting the VPHP is usually not an environmental concern. A risk assessment should be conducted to determine if workers or pedestrians near the exhaust outlet could be exposed to VPHP. If necessary, catalytic converters can be installed to degrade VPHP in the exhaust to eliminate this risk.

- 1Janke, M., and G. Lauth. “Biodecontamination of a Large Volume Filling Room with Hydrogen Peroxide Vapor.” Pharmaceutical Engineering 17, no. 4 (July-August 1997).

- 2International Society for Pharmaceutical Engineering. “Takara Bio Inc.” Pharmaceutical Engineering 36, no. 3. Facility of the Year Supplement (May-June 2016): 42–47.

Decontamination

The intended decontamination frequency should also be considered during the preliminary design phase. Doors can be a source of VPHP egress from the target zone. For large spaces, carefully controlling differential pressures between rooms and off-hours treatment is the preferred means of VPHP containment. For infrequent use, target zones adjacent to occupied areas can be locked and sealed with painter’s tape. Doors with pneumatic seals are much preferred for frequently used applications, such as decontamination airlocks.

Process monitoring

Process monitoring should also be considered during the design phase. Low-level electrochemical sensors programmed to alarm at 1.0 or 0.5 parts per million (ppm) are usually installed in areas where VPHP leakage could pose a risk to personnel. Process validation is usually performed using biological indicators (BIs). For applications that are used often, high-level electrochemical VPHP sensors may be installed to measure and record concentrations. Standard relative humidity (RH) probes will read more accurately when exposed to VPHP when equipped with the addition of catalytic caps.

Exposed surfaces

VPHP is a surface decontaminant; it will not kill microbes protected by a covering. These occluded surfaces should be minimized. A standard operating procedure (SOP) that specifies item positioning or loading can make the decontamination process reliable and repeatable. Periodic cleaning procedures should also be incorporated in the SOP.

Design

Design factors to be considered are:

- Integrated VPHP generators lack integrated dehumidification, catalyst control, and pressure control because they are designed to work with other HVAC system components. Most pharmaceutical production integrations are controlled by a master programmable logic control in coordination with the building management system (BMS).

- Delivering VPHP from the generator to the target enclosure normally requires a single-pass dehumidified airflow of 60–200 cubic meters per hour (m3/hr) using an insulated, dedicated piping system made of a suitable polymer, such as chlorinated polyvinyl chloride or polypropylene. Noncondensing temperatures and unrestricted flow determine pipe length and diameter. Target zones are selected and decontaminated using a supply manifold. When required, balancing dampers establish proper airflows to discrete target zones. Sequential decontamination is typical for multiple target zones, with one set of rooms being decontaminated while the prior set undergoes the dwell or aeration phase.

- Well-conceived systems require no prepping, sealing, or portable fans for effective VPHP distribution. Airflows are balanced to eliminate or minimize the need for the pretreatment sealing. Airflows are also designed to supply, distribute, and eliminate hydrogen peroxide efficiently.

Retrofit or new construction

The most efficient VPHP system integrations can be realized with new construction. Here a modern BMS optimizes and integrates airflows, valves, dampers, piping, and controls. Despite this, most integrated decontamination systems are retrofitted into existing facilities. Retrofitting a facility with a recirculating HVAC system and an integrated VPHP unit is easier than installing a multiroom system in a facility with single-pass air. A recirculating HVAC system needs a single injection port to serve the entire zone, while a single-pass HVAC needs at least one port per room. In some cases, the main trunk exhaust air of a single-pass HVAC system can be redirected to the main supply trunk to create a recirculating system that is used only during decontamination. As with the recirculating system, a single point of injection can be used to decontaminate the entire zone.

HEPA filters

High-efficiency particulate air (HEPA) filter selection for applications in which they are exposed to the VPHP/airflow is another consideration. Cellulosic materials absorb hydrogen peroxide, so HEPA filters with metal housings and pleat separators are preferable.

Ductwork

Many older facilities have ductwork leakage. Ducts with positive pressure during operation may leak hydrogen peroxide vapor into the mechanical area; this may require the addition of an exhaust fan to prevent concentrations that exceed the permissible exposure level from developing in the mechanical area. Ductwork maintenance should locate and seal points of leakage. The use of handheld or permanently installed low-concentration hydrogen peroxide monitors to determine leakage or concentrations during reentry are an essential part of every application. In most countries, the hydrogen peroxide vapor exposure limit for an 8-hour time-weighted average is 1.0 ppm.

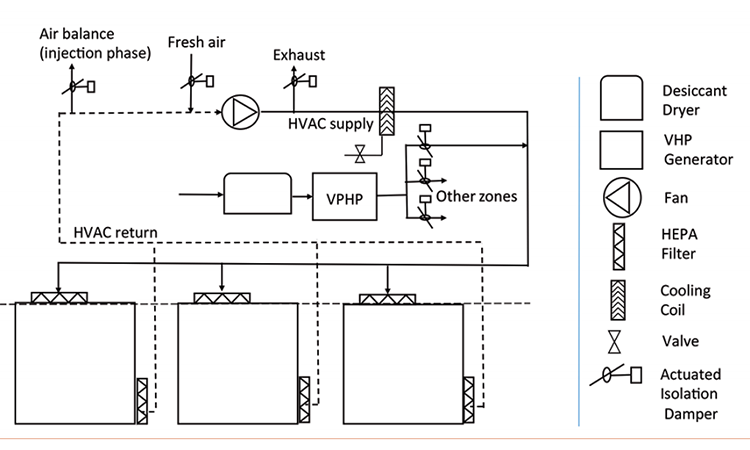

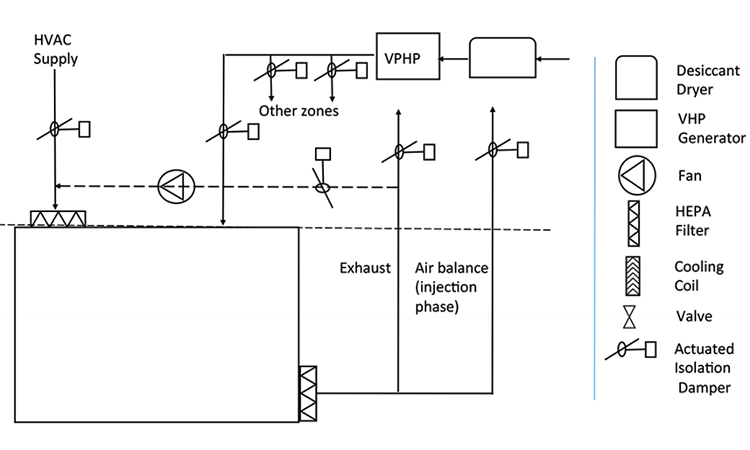

HVAC schematics

Figure 1 shows a typical cleanroom HVAC with a recirculating configuration, an integrated VPHP generator, and a continuous desiccant system. VPHP is injected into the central supply duct and distributed throughout the target zone. Cooling coils are deactivated and their drains are sealed. To avoid condensation they should be allowed to warm and dry before exposing them to VPHP. Hydrogen peroxide condensate can be especially damaging to copper cooling coils with solder joints because of galvanic corrosion. Airflow is balanced to accommodate the VPHP airstream. Once the decontamination phase is complete, VPHP injection is terminated, and fresh air intake and exhaust are maximized to facilitate aeration.

A single-pass HVAC system with an integrated VPHP system is shown in Figure 2. During decontamination the main airflow is shut off while VPHP is injected through well-positioned ports. The air balance and room pressure is maintained with proportional exhaust flow. An additional recirculation duct can be added to distribute the VPHP during the decontamination phase. Normal airflow resumes after the decontamination phase, purging VPHP from the enclosure.

Manifolds

The versatility of a single integrated VPHP generator can be greatly enhanced by pairing it with one or more manifolds: a supply pipe with two or more branches, each equipped with an on/off valve to direct the vapor to the target zone. Manifolds may be layered in succession or can lead to branches equipped with balancing dampers, where injection is directed though multiple ports.

CYCLE PHASES FOR LARGE SPACES

A dehumidification phase is usually conducted prior to VPHP injection. While this phase was historically used to dry and warm isolators and other small enclosures, it also allows higher VPHP concentrations during the decontamination phase. Integrated VPHP systems need a dehumidified airstream to deliver vapor to the target zone. The duration of the dehumidification phase has little to do with reducing the target room RH to a desirable range of 49%–65%. Target enclosure RH and temperature are established by the HVAC system prior to starting the decontamination sequence. The generator's dehumidification phase should be long enough to warm up the distribution piping to avoid condensation when the VPHP injection begins. The subsequent decontamination phase introduces and distributes hydrogen peroxide vapor to the target zone (without producing condensation in the ductwork). An initial subphase called “conditioning” typically uses a higher liquid hydrogen peroxide injection rate to ramp up VPHP concentration.

Once the desired exposure level (time and concentration) has been achieved, the aeration phase is initiated. During aeration, the generator purges VPHP from the distribution pipework while the HVAC system maximizes the percentage of fresh air purging VPHP from the target enclosure. The aeration process can take overnight on a retrofit application when the HVAC system is designed to use a low percentage of fresh air.

FACTORS FOR SUCCESSFUL CYCLES

Three key factors are critical for achieving the desired kill or bioburden-reduction levels with any VPHP system: saturation, distribution, and time.

Saturation

Since hydrogen peroxide is supplied as an aqueous solution, flash vaporization causes a simultaneous rise in both the water and the hydrogen peroxide vapor content of the target enclosure. Maximizing the atmospheric saturation of a peroxide/water vapor mixture at a given enclosure temperature achieves the shortest, most efficacious cycle3 for large-volume applications. Introducing and dispersing VPHP into an enclosure while remaining below the dew point remains a key factor in the development of consistent, robust cycles. Preventing condensation greatly enhances distribution and efficacy, maximizes concentration, expedites VPHP passage through HEPA filters, and shortens cycle time. Well-developed noncondensing cycles also prevent potential material compatibility issues and prolonged aeration times.

Distribution

Standard recirculating HVAC configurations typically do an excellent job of distributing hydrogen peroxide vapor to all target enclosure surfaces. For rooms that use single-pass air, efficient vapor distribution is achieved by injecting at flow rates that create turbulence and mixing through well-positioned ports. This eliminates the need for mixing fans, as are commonly used with portable decontamination systems. Decontamination of large suites with integrated VPHP systems have been successfully validated without the use of fans in the rooms.

Time

Most installations are validated using the “overkill” approach; this determines the exposure time required to inactivate biological indicators (typically 10e6). These are placed in a geometric pattern throughout the enclosure, with emphasis on placement in those areas determined to be least exposed using chemical indicators. Once the injection time is determined to just achieve a 6-log reduction, a factor is used to increase injection time to achieve overkill. For example, a factor of 1.3 times the initial decontamination phase may be used for overkill. This will compensate for potential environmental variability in future runs.

- 3STERIS Corporation. Cycle Development Guide. VPHP Biodecontamination Products. Parameters That Affect Decontamination Efficacy. Part no. P129372-711. 2006.

RABS, CHAMBERS, AND PASS-THROUGHS

In addition to their use in cleanrooms and suites, integrated VPHP systems can decontaminate a variety of other enclosures, including restricted access barrier systems (RABS), decontamination chambers, and pass-throughs, using specially designed manifolds. Using integrated VPHP to decontaminate a room containing a RABS allows the system to be decontaminated with the doors shut and all filling components in place, just as in an isolator. The RABS air-handling system draws VPHP from the room either directly (active RABS) or via the room’s ceiling-mounted HEPA filters (passive RABS) and exhausts it back into the room. All interior surfaces are decontaminated while the doors remain closed. In a single-pass configuration, VPHP is piped directly into isolators and then exhausted. Despite the similarities, the current minimum classification of the background environment is ISO Class 7 for RABS vs. ISO Class 8 for isolators.

Gaseous decontamination chambers and pass-throughs are a common fixture in many production areas. Integrated VPHP systems are often used during regular production hours to serve pass-throughs or chambers and are dedicated to the decontamination of clean-room suites during nightly or weekend shutdowns. Chambers and pass-throughs can be designed to have highly efficient cycles. One of the most rapid total cycle times is about 12 minutes. 4

Examples

The time required to decontaminate an enclosure depends largely on the total volume and the fresh air exchange rate during aeration. Two examples of validated applications are shown in Table B.

CONCLUSION

Integrated VPHP systems are becoming more common, particularly in Europe and Asia—most often for ISO Class 7 and higher environments—indicating that this technology has gained industry acceptance. HVAC systems are typically used for one or more of the process steps, including VPHP supply, distribution, and aeration. The initiative for an integrated VPHP system may come from the consulting engineer or from the end user organization. Implementation involves cross-functional teams with a thorough knowledge of production processes. Although new construction allows the greatest flexibility for integration, most integrated VPHP systems are placed in existing facilities. The versatility of integrated installations can be greatly enhanced with the use of manifolds operated by the BMS to direct hydrogen peroxide vapor to any number of enclosures and HVAC systems, including cleanroom suites, rooms containing RABS, pass-throughs, decontamination chambers, and isolators.

- 4Bergan, B., and M. Greenbank. “Case Study: The Selection and Evaluation of an Isolator System for Rapid Response Pharmaceutical Compounding.” Presented at the Eighth Pharmaceutical Isolator Conference, Warwick, England, 2004, and the ISPE Barrier Isolation Technology Forum, Prague, Czech Republic, 2005. http://www.aseptd.com/case_study/baxter_case_study.pdf