Agile Lab to Launch, Continuous Manufacturing, & Novel Therapies: The Future of Pharma Process Development & Manufacturing

The needs of patients provide the impetus to challenge the notion of “this is the way we’ve always done it”.

Many of our colleagues are taking on the challenge of rethinking the old ways. They are collaborating with each other and the regulatory agencies to take effective steps to remain at the forefront of regulatory science and innovation. Why? In order to ensure the continued delivery of effective medicines.

As we consider the future of pharmaceutical process development and manufacturing, we must identify the emerging needs of patients, assess the impact of these needs on manufacturing and process verification options, and work collaboratively to develop good practices. In addition, there is also a need to be intentional: to shape the knowledge management landscape and recognize the inherent culture changes required to be agile in today’s world.

Trends related to the emerging needs of patients include how to supply small batches quickly and with consistent quality. This includes the rapid evolution towards continuous manufacturing (CM) to meet these ever-changing supply chain requirements. As we see more companies successfully producing products this way, there is growing evidence to support how continuous manufacturing offers batch size flexibility, smaller manufacturing footprints, and streamlined development without the old challenges of scaling. The lessened angst around scale-up means we can accelerate the development to commercial launch process.

Whether a batch or continuous focus, colleagues are investing even more time and energy into implementing holistic “fume hood to launch” strategies with emphasis on data analytics. It is increasingly possible to bridge the gap between lab-scale, pilot-scale and small-scale commercial manufacturing by leveraging modular and agile process design and equipment. These strategies provide business value by building quality into the process, aligns process robustness with process validation, and lets companies be agile as they balance current needs with projected scales and unit operations.

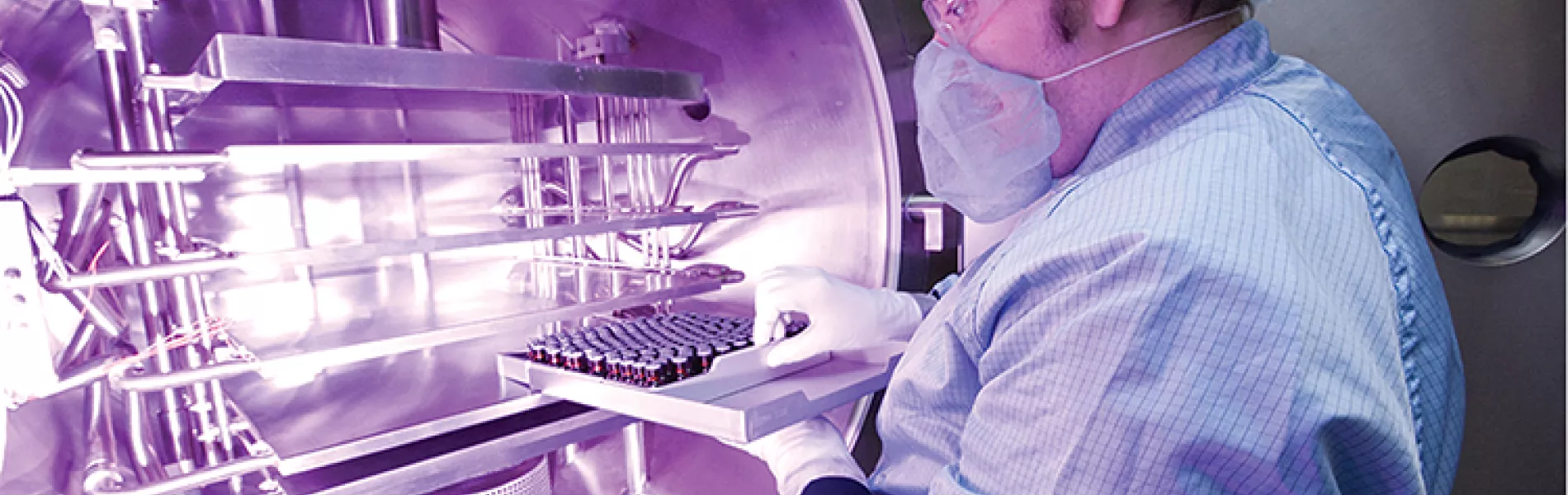

Other trends related to the emerging needs of patients include transformation around how we treat severe genetic diseases, e.g., novel cell and gene therapies. This means rethinking traditional packaging. It means understanding the product quality considerations around novel therapies. It means appreciating the demanding containment strategies that gene and viral therapy processes can require.

Finally, these emerging needs of patients deserve a responsive life sciences community. A culture of collaboration recognizes that how we work and where we work are just as important as the hardware and software that we use to enable robust manufacturing processes. Thoughtfully designed spaces fostering collaboration, breaking visual barriers, and encouraging sharing are key. Consideration given to how these spaces encourage real-time interaction with the manufacturing space, like tracking of facility health metrics to ensure robust operation of equipment, gives rise to agile thinking. An effective Knowledge Management strategy coupled with a workspace that supports collaboration is key to long term success. The ISPE Good Practice Guide and the ISPE Product Quality Lifecycle Implementation (PQLI) initiative are two great examples of collaborating to develop best practices.

The needs of patients must provide the impetus to challenge the notion of “this is the way we’ve always done it”. New transformative therapies inherently bring new challenges, but they also present us with new opportunities. For both these new therapies and the traditional therapies, there is opportunity to leverage innovative manufacturing processes, collective guidance, and an agile mindset to adapt to the current needs of patients.

It takes the commitment of our pharmaceutical community to work together: To challenge the old ways. To embrace new thinking. To make it real.

Check out the 2019 ISPE Annual Meeting & Expo Process Development and Manufacturing Track, to get a glimpse of what we have in store.

Get ready to Modernize. Globalize. Transform.

With 6 extensive education tracks, 85+ hours of targeted technical sessions, 24+ hours of networking opportunities, 200+ exhibitors, Discovery Stage in Expo Hall, 2 days of in-depth classroom training & more, the 2019 ISPE Annual Meeting & Expo is an event you don’t want to miss! Take advantage of the registration discount that is available through 17 September and register today.