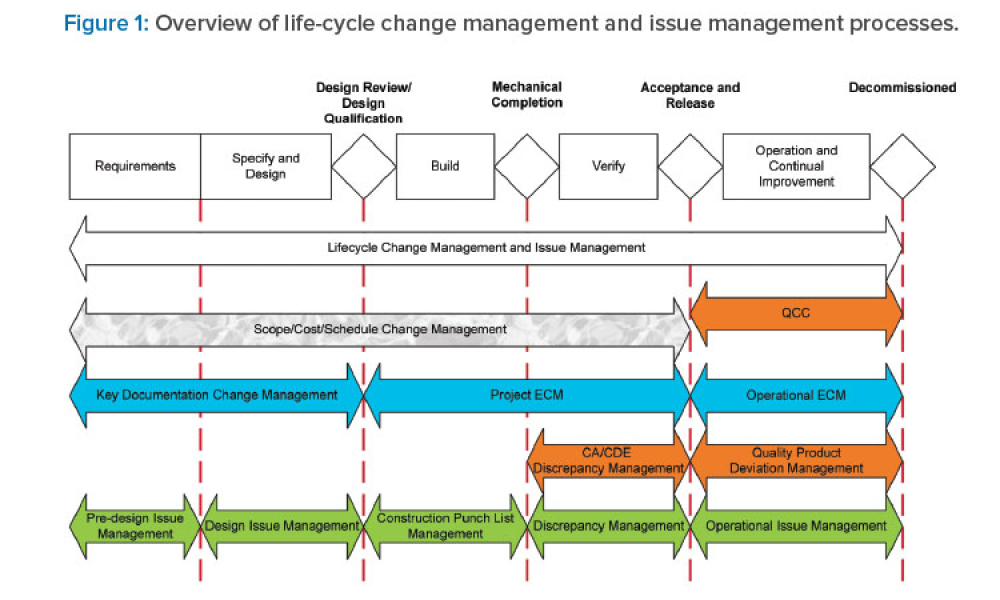

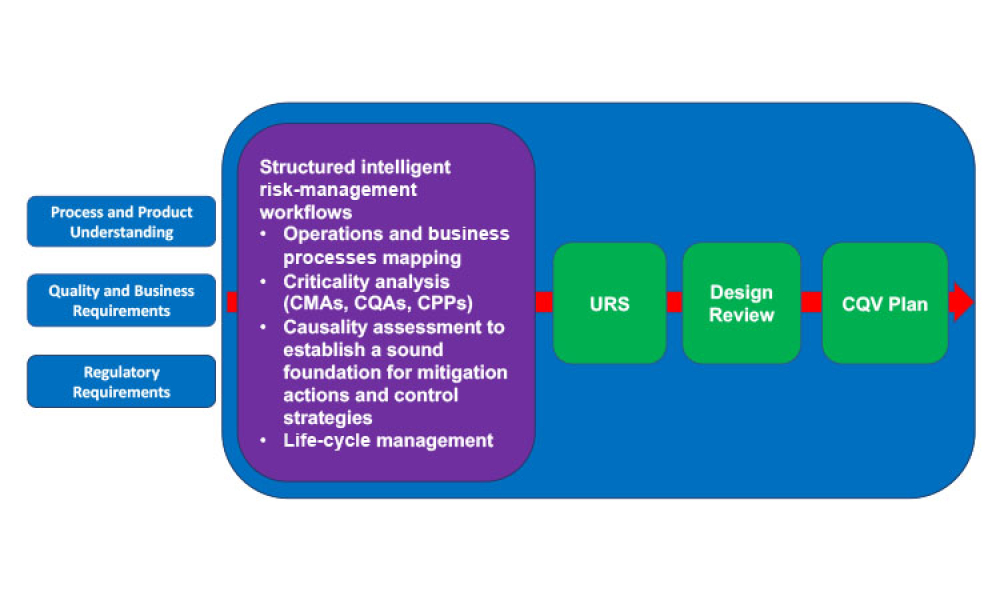

Commissioning and Qualification (C&Q) are terms and processes related to the manufacturing of pharmaceutical or biotechnology products. Each term represents a scope of work that is part of a larger framework for making sure that a facility —and the equipment in it— will function as required and be approved by the regulatory agencies that have jurisdiction over that facility.

Produced by pharmaceutical manufacturing industry professionals, ISPE offers a variety of resources to help narrow interpretation of regulatory standards for improved compliance and quality, efficiency, and cost reductions.

Related Guidance Documents

Commissioning & Qualification (6)

- Good Practice Guide: C&Q of Pharma Water & Steam Systems 2nd Edition

- Good Practice Guide: Decommissioning Pharma Equipment & Facilities

- Good Practice Guide: Controlled Temperature Chambers 2nd Edition

- ISPE Baseline Guide: C&Q (2nd Ed) Download - USD

- GAMP Good Practice Guide: Testing GxP Systems 2nd Edition

- GAMP Good Practice Guide: Computerized GCP Systems & Data

Critical Utilities (1)

Data Integrity (1)

GAMP® (2)

Quality by Design (1)

Regulatory (1)

Sustainable Facilities, HVAC, & Controlled Environments (1)

Validation (1)

Community Discussions

Community Discussions

Nov 04, 2024

Nov 02, 2024

Nov 02, 2024

Nov 02, 2024

Nov 02, 2024

Oct 30, 2024

Webinars Related to Commissioning and Qualification

iSpeak Blog Posts Related to Commissioning and Qualification

Pharmaceutical Engineering Magazine Articles

Videos Related to Commissioning and Qualification

Training Courses Related To Commissioning and Qualification

Commissioning and Qualification Training Course

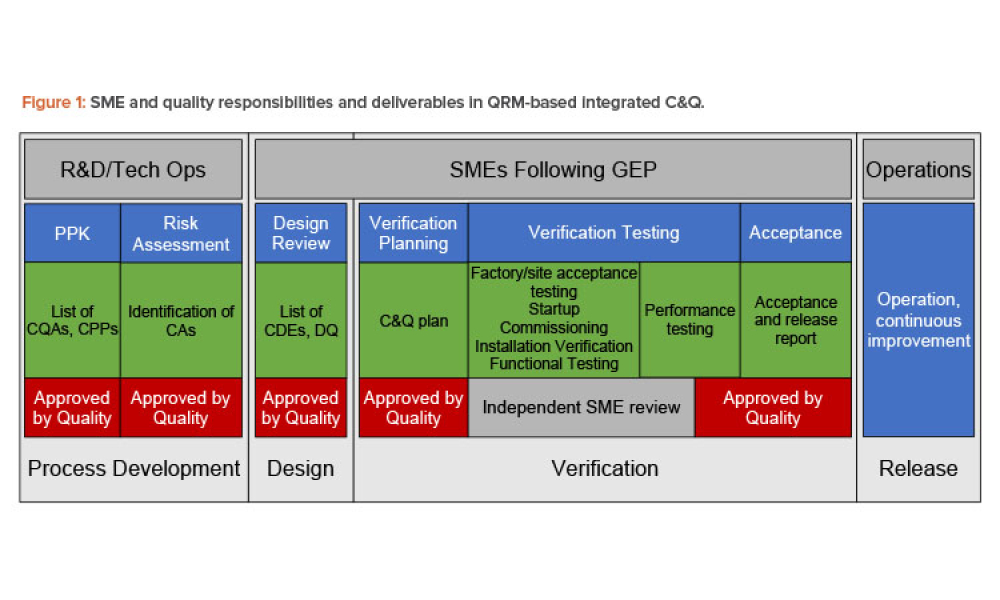

Worldwide Regulatory expectations and guidance as led by FDA and the EU have stated that all Pharmaceutical Quality Systems should apply a QRM (Quality Risk Management) approach. Through interactive workshops, this course will explain and apply the science and risk-based approach to integrated lifecycle Commissioning & Qualification by conducting verification of systems, equipment and facilities in accordance with the recently issued 2nd Edition Guide, ICH documents Q8 (R2), Q9, and Q10, current Regulatory Guidance, industry best practices, and ASTM E2500.

Facilities Management Training Course

This interactive course will provide the learner with tools on how to implement a sustainable approach to a risk-based C&Q program, integrate the new C&Q program into existing quality systems, Quality Assurance and Engineering Management Systems and define organizational capabilities to support the new C&Q program.

Pharma Facilities Project Management Training Course

Specifically targeted to the needs of facility projects within the regulated pharmaceutical industry and demonstrates the value inherent in the use of “good practice” project management in the regulated pharmaceutical environment.

Concept and Discussion Papers

Stage 2 Process Validation: Process Performance Qualification Batches

Authors: Mette Bryder (Lundbeck), Harold Etling (Eli Lilly), Jeff Fleming (Pfizer), Yanhui Hu…

Controlled Temperature Chamber Mapping

1 Introduction This document provides guidance on good practices for the mapping of controlled…

Pharmaceutical Job Board

Featured Conferences